EN

Painting Equipment with Color Coated Steel Line Can Produce PPGI Ppal

Product Description:

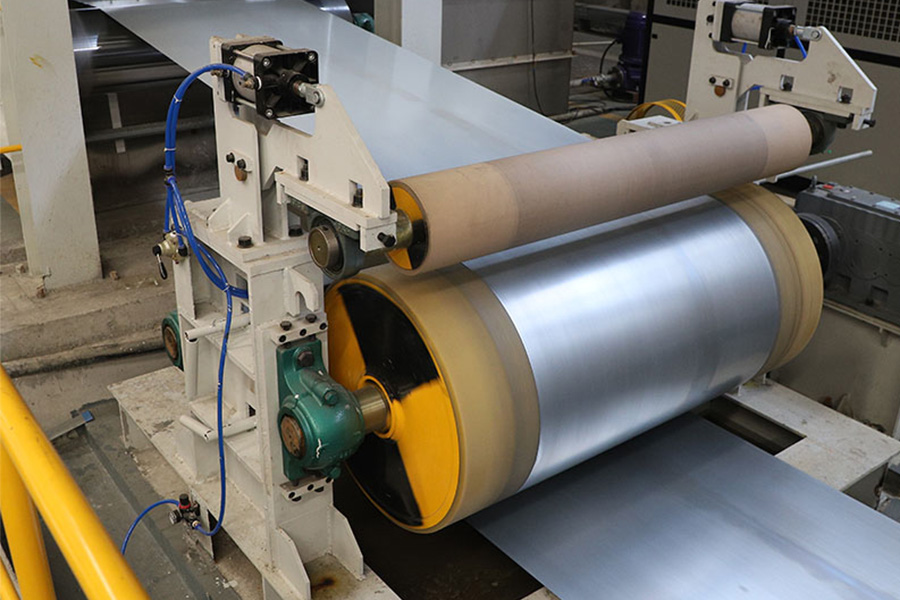

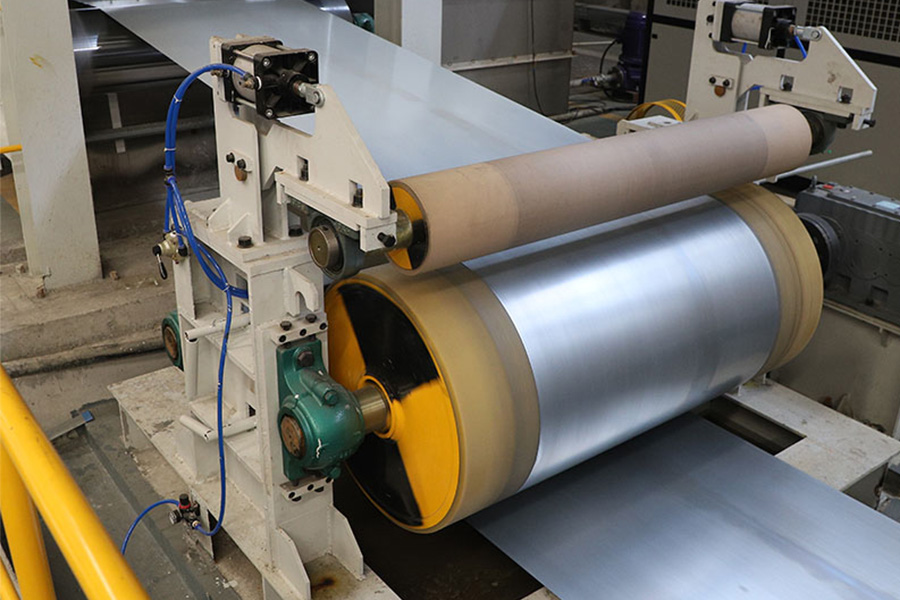

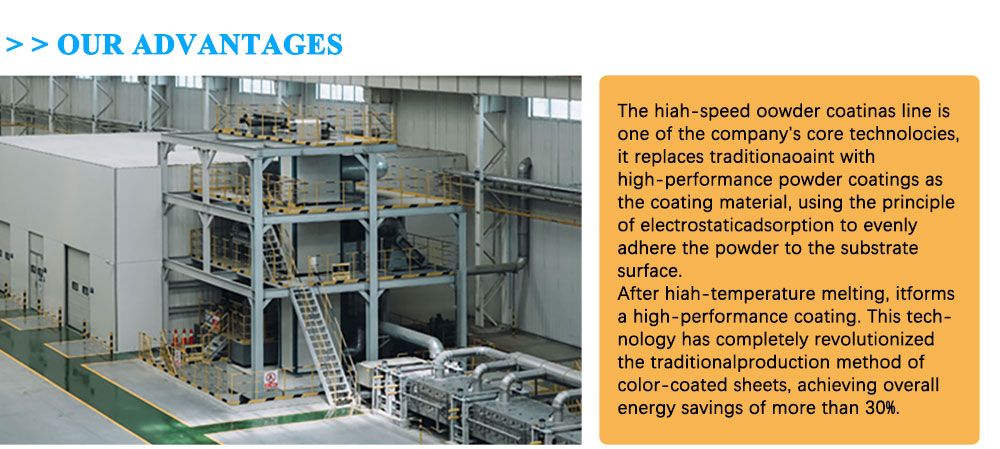

The color coating unit adopts double-coating double-bakingmodel and hot air circulation heating orocess.

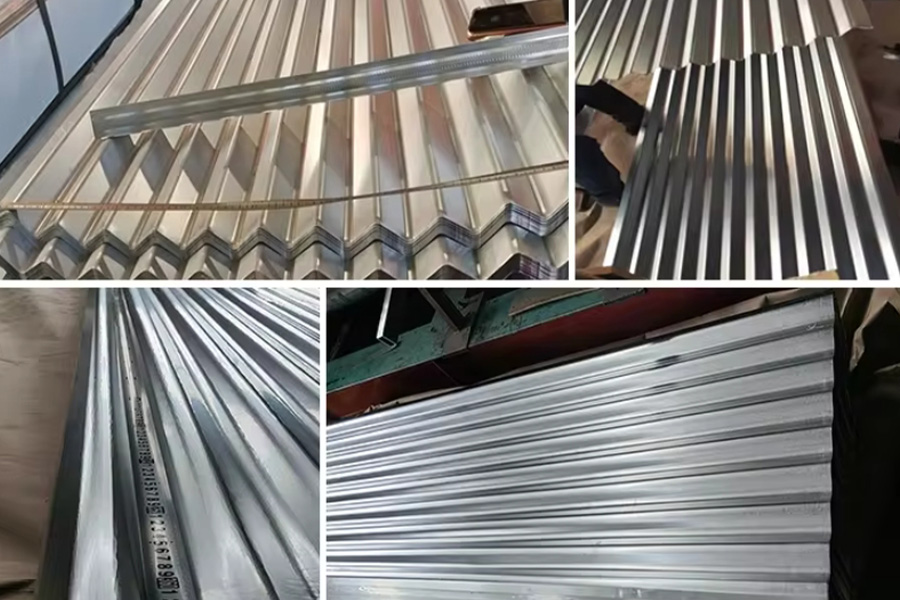

Material of base plate: electro-galvanized plate, hot-diogalvanized plate, hot dip Al-Zn plate, cold-rolled steel plate, aluminum coils etc.

Inquiry Now

- Product Description

- Inquiry Now

- Related Products

- Customer Reviews

Product Description

| Model NO. | Paint Color Coating Line |

| Substrate | Steel |

| Certification | CE, ISO, SGS |

| Condition | New |

| Heating Method | Electric, Steam, Hot Water |

| Operation Mode | Automatic, Semi Automatic, Manual |

| Material of Kettle | Steel, Ceramic |

| Material of Tank | PP, Moortone |

| Installation | Concluded as Customer Required |

| Application | Bridge and Highway, Industry, Construction |

| Delivery Term | 3-5 Months |

| Transport Package | as Required |

| Specification | Customized |

| Production Capacity | 20 Sets/ Year |

| Capacity | 30000-300000tons |

| Production line | Substrate type | Process speed(m/min) | Substrate thickness(mm) | Substrate width(mm) | Production line length (m) | Energy medium | Process flow |

| Pre-painted coil production line forhome appliances | Galvanized/ Aluminum-zinc/ Zinc-aluminum-magnesium/ Stainless steel | 20-120 | 0.3-1.5 | 700-1650 | 100-200 | Water/ Electricity/ Gas | Uncoiling → Head cutting → Riveting → burring → inlet loose sleeve - alkali washing → rigid washing → hot water rinsing → regulating tank - hot water rinsing → drying → chemical treatment → drying → cooling → initial coating → initial coating baking and curing → initial coating cooling - drying - fine coating - fine coating baking and curing → fine coating cooling → drying → outlet loose sleeve → Quality inspection → slitting one roll and taking → packaging and storage |

| Pre-painted coil production line forconstruction panels | Galvanized/Aluminum-zinc/Zinc-aluminum-magnesium/ Stainless steel | 20-120 | 0.1-1.2 | 700-1650 | 70-200 | Water/ Electricity/ Gas | Uncoiling → Head cutting → Riveting → burring → inlet loose sleeve - alkali washing → rigid washing → hot water rinsing → regulating tank - hot water rinsing → drying → chemical treatment → drying → cooling → initial coating → initial coating baking and curing → initial coating cooling - drying - fine coating - fine coating baking and curing → fine coating cooling → drying → outlet loose sleeve → Quality inspection → slitting one roll and taking → packaging and storage |

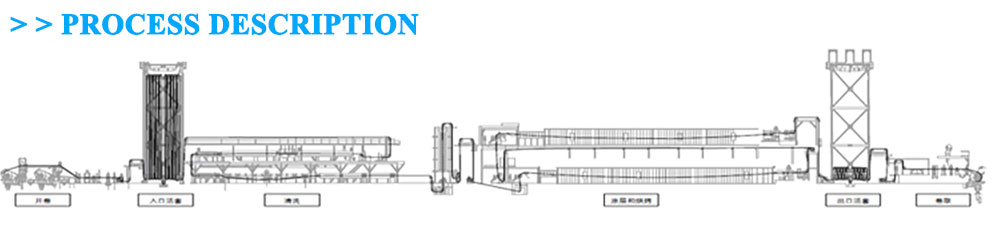

The 13 core processes of the color-coated steel production line form a precisely coordinated industrial chain:

1.Uncoiling→2.Seam Welding→3.Entry Loop→4.Pretreatment→5.Primer Coating→6.Primer Curing→

7.Top Coating→8.Top Curing→9.Water Cooling & Air Drying→10.Exit Loop→11.Inspection→12.Rewinding→⑬13.Packaging

Inquiry Now