EN

Continuous Galvanizing Line Hot DIP Galvanizing Equipment Hot DIP Galvanizing Line

Product Description:

Continuous galvanizing units incude galvanizing, galvanizing aluminum macnesium, aluminum zinc silicon, aluminum olating oickling + galvanizing combined units, as well as color coating, degreasing, and leveling and straightening units.

Inquiry Now

- Product Description

- Inquiry Now

- Related Products

- Customer Reviews

Product Description

| Model NO. | Hot dip galvanizing line |

| Substrate | Steel |

| Certification | CE, ISO, SGS |

| Condition | New |

| Heating Method | Electric, Steam, Hot Water |

| Operation Mode | Automatic, Semi Automatic, Manual |

| Material of Kettle | Steel, Ceramic |

| Material of Tank | PP, Moortone |

| Installation | Concluded as Customer Required |

| Application | Bridge and Highway, Industry, Construction |

| Delivery Term | Fob CIF CNF |

| OEM, ODM | Available |

| Transport Package | as Required |

| Specification | Customized |

| Production Capacity | 150 Sets/ Years |

| Production line | Substrate type | Process Speed(m/min) | Substrate thickness(mm) | Substrate width(mm) | Coating thickness(g/m*m) | Energy medium | Process flow |

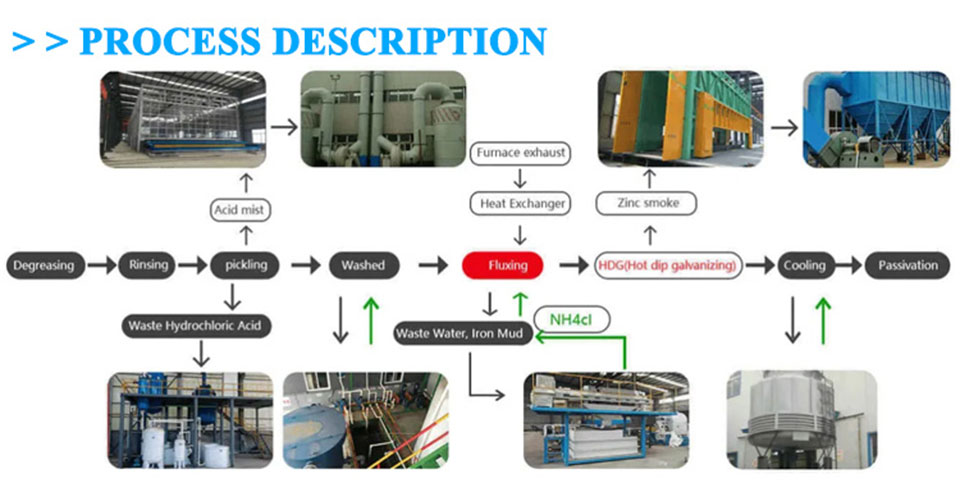

| Hot-dip galvanizing line | Cold-rolled plain carbon steel,Low-alloy steel coil | 50-260 | 0.12-4.5 | 300-1600 | 40-120 | Water/ Electricity/ Gas | uncoling → shearing → welding → looper → degreasing and cleaning → drying → annealing →galvanizing(aluminum-zinc coating, zinc-aluminum-maqnesium coating)→ cooling - skin passing ->tension leveling -passivation or anti-fingerprint treatment → drying → looper → oll coating → shearing → recolling |

| Hot-dip galvalume line | Cold-rolled plain carbon steel,Low-alloy steel coil | 50-260 | 0.12-4.5 | 300-1600 | 40-120 | Water/ Electricity/ Gas | |

| Hot-dip ZAM Line | Cold-rolled plain carbon steel,Low-alloy steel coil | 50-260 | 0.3-4.5 | 300-1600 | 40-275 | Water/ Electricity/ Gas | |

| Electrogalvanizing tin line | MR type, D type.L type tinplate substrate | 100-450 | 0.15-0.5 | 600-1200 | 1.1-11.2 | Water/ Electricity/ Gas | unwinding -> shearina - welding > looner -> chemical deareasing > electrolytic degreasing -> rinsing -electrolytic pickling → rinsing → tin plating - rinsing and drying → soft annealing → quenching →electrolytic passivation → rinsing and drying → oil coating → looper → shearing → recoiling |

Taking digitalization as core technology, the newly built HDG production line will be a fully cosed loop HbG production line, which owns advanced, hiohly efficient, and world-first inventive production process arrangement and the production line desion is optimized with the concept of reduction and recycling,

Inquiry Now